- Description

- Price and Availability

- Downloads & Specs

- Reviews

Description

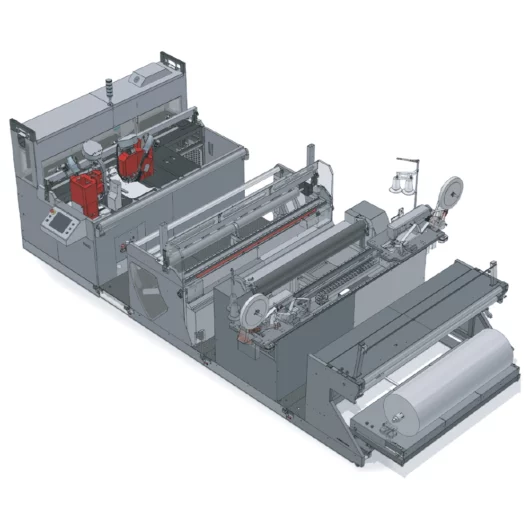

Automated Sewing, Eyeleting & Cutting System for Textile Finishing

The TexWiz is a purpose-built finishing system for textile-based signage, offering an all-in-one solution that combines automated sewing, eyeleting, and cutting into a single production workflow. Ideal for fabric banners, flags, and mesh materials, the TexWiz eliminates manual handling, boosts output efficiency, and ensures high-quality, consistent results.

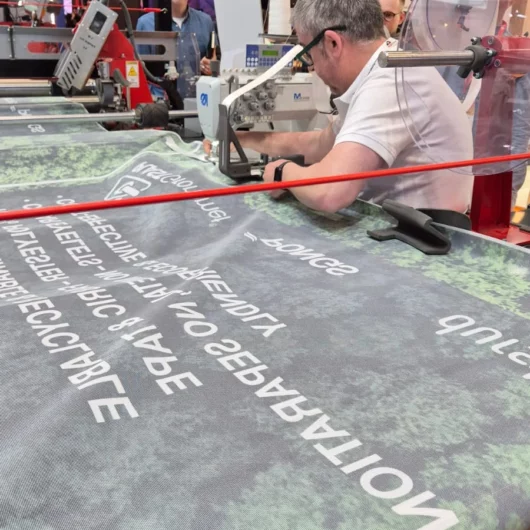

Designed to accommodate a wide range of fabric substrates, the TexWiz is especially suited for producers of airmesh banners, polyester flags, and other textile-based signage requiring sewn hems and reinforced eyelet applications. Its dual sewing module enables rapid, automated hemming at industrial-grade speed and precision, reducing dependence on manual labour while increasing finishing accuracy.

? Core Capabilities

The TexWiz automates three key finishing processes:

-

Sewing (Hemming): Equipped with a dual sewing module, it simultaneously hems both edges of textile material, significantly increasing throughput over traditional single-head solutions. Perfect for light and medium-weight fabrics.

-

Eyeleting: Integrated eyelet setting module adds metal eyelets at defined intervals, creating reinforced hanging points for banners and flags.

-

Cutting: The system performs clean, accurate cross-cuts to deliver banners at pre-set lengths — whether you’re producing roll-to-roll or roll-to-banner outputs.

? Technical Specifications

-

Working width: 600 mm to 3200 mm

-

Max roll diameter: Ø500 mm

-

Material type: Fabric-based substrates (airmesh, polyester, flag textiles, and similar)

-

Output modes:

-

Roll-to-roll: Ideal for high-volume airmesh banner production

-

Roll-to-banner: Suitable for cut-to-length flag or banner applications

-

-

Sewing module: Dual-machine setup for simultaneous double-edge hemming

-

Eyeleting spacing: Programmable to suit installation requirements

-

Cutting method: Integrated cutter with defined interval programming

⚙️ Performance & Efficiency

The TexWiz is built on the robust and proven All-in-One platform but optimised for textile materials. It transforms multi-step fabric finishing into a single, seamless process.

Advantages include:

-

Increased speed through dual sewing operation

-

Reduced rework and material waste due to automation consistency

-

Lower labour requirements compared to manual sewing and eyeleting

-

Precise hem alignment across long runs of flexible textiles

-

Compact design suitable for small to mid-size production facilities

? Workflow & Automation

The TexWiz supports both roll-to-roll and roll-to-banner output configurations, making it highly versatile across textile signage needs:

-

Roll-to-Roll Mode: Automatically winds finished fabric onto a new roll — ideal for fence mesh and long-run textile banners.

-

Roll-to-Banner Mode: Cuts material to pre-set lengths after hemming and eyeleting — perfect for individual flags or signage panels.

Each process is fully synchronised, with programmable parameters for spacing, cut length, and operation mode.

?? Operator Benefits

-

Single-operator workflow: Designed for hands-off processing with basic supervision

-

Consistent output quality: Minimal variation between units produced

-

Easy to maintain: Based on widely available sewing machine technology

-

Safety first: Enclosed moving parts and clear emergency stop access points

✅ Summary of Key Features

-

Dual-integrated sewing heads for high-speed hemming

-

Combined eyeleting and cutting system

-

Adjustable working width up to 3200 mm

-

Supports both roll-to-roll and roll-to-banner production

-

Optimised for fabric substrates like airmesh and polyester

-

Compact and scalable for mid-size signage producers

Price and Availability

| Item No. | Description | This product is only available to printers and signmakers. |

|---|---|---|

| TEXWIZ | Level 9+ - TexWiz |