- Description

- Price and Availability

- Downloads & Specs

- Reviews

Description

Compact All-in-One Finishing System for Medium-Volume Banner Production

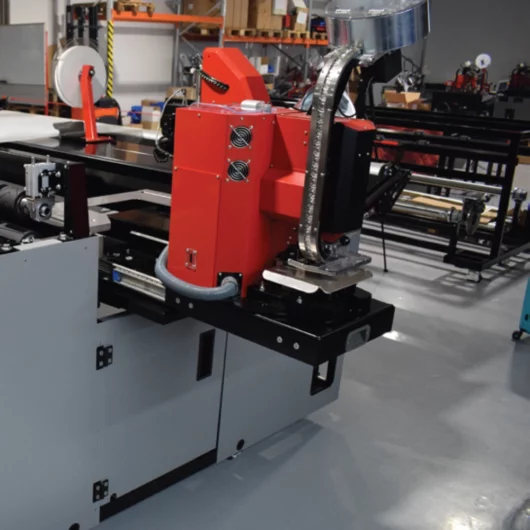

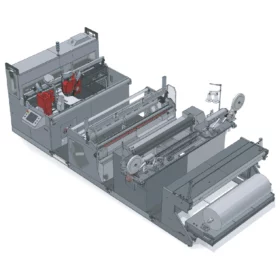

The All-in-One Edge is a precision-engineered banner finishing system that combines welding, eyeleting, and cutting into one automated, space-efficient unit. Tailored for medium-sized signage and large-format print businesses, it provides a streamlined solution for banner production without compromising on output quality, safety, or adaptability.

? Core Capabilities

At its core, the All-in-One Edge is a roll-to-banner finishing machine. It’s designed to take in media directly from a roll and output banners that are hemmed, eyeleted, and cut to length — ready for delivery or installation.

-

Welding: Hem welding provides reinforced banner edges for greater durability in outdoor and high-stress environments. A hem welding kit is required and can be expanded with tape and slitter kits for tailored finishing.

-

Eyeleting: Equipped with two electric Autocross machines, it places eyelets automatically at selectable intervals — ensuring consistent tension and professional presentation. The system can also rotate 180º to handle short-side or manual eyeleting tasks.

-

Cutting: An adjustable gantry allows for single or double cuts, optimising production for narrow or standard-width banners. Double cuts are particularly useful when producing clean panel splits for mesh or multi-section installations.

? Technical Specifications

-

Working width: 600 mm to 3200 mm (adjustable to banner roll size)

-

Max roll diameter: Ø500 mm

-

Media type: Roll-fed banner material (PVC, mesh, and other flexible substrates)

-

Output method: Roll-to-banner with length-based cut intervals (set constant across the roll)

-

Cutting options: Single and double cutting (dual cut mode available for specific requirements)

-

Eyelet spacing: Fully programmable via onboard screen interface

-

Tension control: Braked unwind mechanism maintains consistent media feed tension

-

Cutting gantry: Adjustable width to reduce movement for narrower banners and improve cycle times

-

Media detection: Automatic stop when roll ends using a built-in media sensor

-

Safety features:

-

Full enclosure of moving parts

-

Rope-pull emergency stop switch

-

Multiple emergency stop buttons

-

Protected cutting gantry for safe operation

-

? Connectivity & Control

The All-in-One Edge is built for connected workflows. It includes remote support access via Ethernet or Wi-Fi, allowing for:

-

Software updates

-

Remote diagnostics and error monitoring

-

Efficient troubleshooting and maintenance planning

This means your investment remains up-to-date, secure, and supported without requiring technician visits for every issue.

? Optional Kits (Customise Your Workflow)

To maximise versatility, the All-in-One Edge supports a modular upgrade path through optional kits:

-

Hem Welding Kit – Includes two welders, hemming guides, control electronics, and extra shaft. Required for any hem-based finishing.

-

Tape Welding Kit – Adds tape dispensers and guides. Must be ordered with the hem welding kit.

-

In-Line Slitter Kit – Adjustable left-side slitting from 10 mm to 50 mm; right side has no limitation. Enables resizing of media before welding.

-

Roll Edge Alignment Kit – Pneumatic support system that shifts the unwind shaft left or right automatically to maintain edge alignment.

-

Roll-to-Roll Kit – Adds a rewinding system (air shaft + support elements) for continuous production of fence mesh or banners finished onto a roll.

-

Vision System Kit – Camera-assisted system that reads pre-printed cut and eyelet marks for precision alignment.

These kits allow users to scale functionality as business needs evolve, ensuring long-term ROI and production flexibility.

⏱️ Performance Benchmarking

| Finishing Type | Time to Finish 50 m Roll |

|---|---|

| Single Cut | 10 minutes (All-in-One Edge) |

| Double Cut | 16–17 minutes (All-in-One Edge) |

Compared to the All-in-One model: faster processing, but the Edge offers space and cost savings better suited for mid-volume operations.

?? Designed for One-Person Operation

With a compact footprint and intelligent automation, the All-in-One Edge is built for lean teams. A single operator can load rolls, initiate production, and monitor the machine without constant supervision.

Key efficiency features:

-

User-friendly screen interface

-

Programmable tasks and intervals

-

Fast kit-based reconfiguration

-

Built-in safety systems reduce downtime and risk

? Built-In Safety & Compliance

Every operational zone is physically shielded. The system includes:

-

Full protection around the cutting gantry

-

Rope-pull emergency stop

-

Integrated emergency stop buttons

-

Design compliant with industrial safety standards for equipment in production environments

Price and Availability

| Item No. | Description | This product is only available to printers and signmakers. |

|---|---|---|

| AIOEDGE | Level 9+ - All In One Edge |